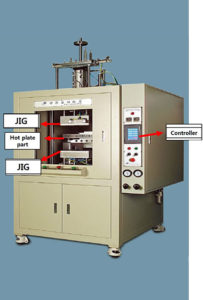

Hot plate welder

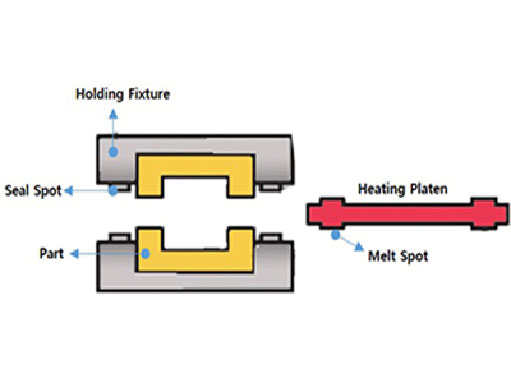

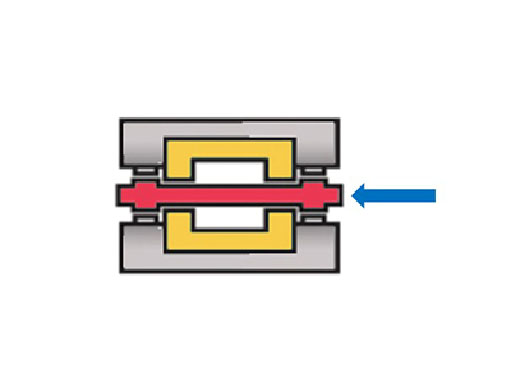

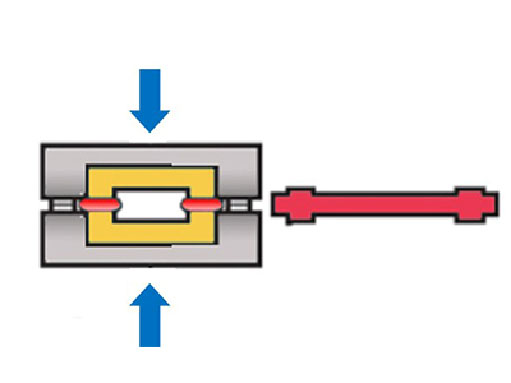

To heat the part joint area, a thermally heated platen is placed between the part halves. The holding fixtures close to

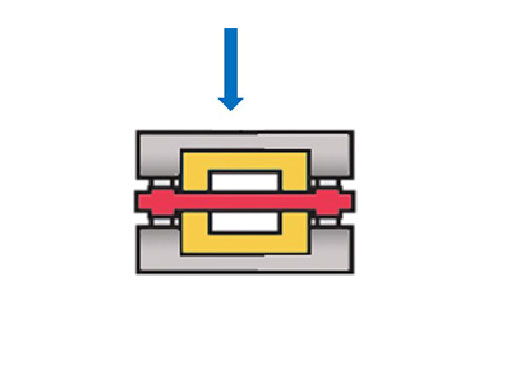

compress and melt the part. Compression continue until thoroughly melt the part. After the joint area reaches molten

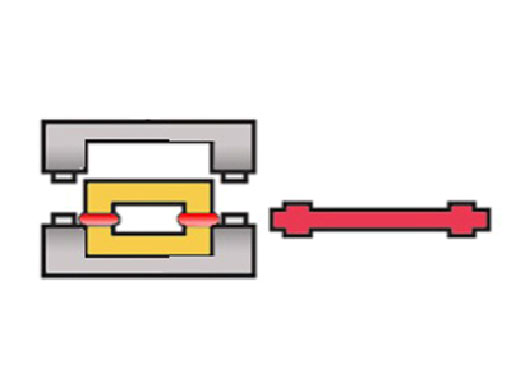

temperature, the heat platen is withdrawn. And force the two parts together and cool the parts until firm.

Caution

- .In case of low temperature, there is not enough melting layer to diffuse and the heating time becomes longer In case of high temperature, direction of polymer at melting part rotates.

- In case of short heating time, plastic layer is not enough. In case of long heating time, direction of plastic chain polymer is changed

- Long off time : Occur heating damage of melting layer by contact with air and interfere melting.

Components

- Jig : where the parts are placed.

- Heated platen : heat the part joint area.

- Driver equipment : Move Jig and heated platen.

- Controller : control movement of machine & temperature.

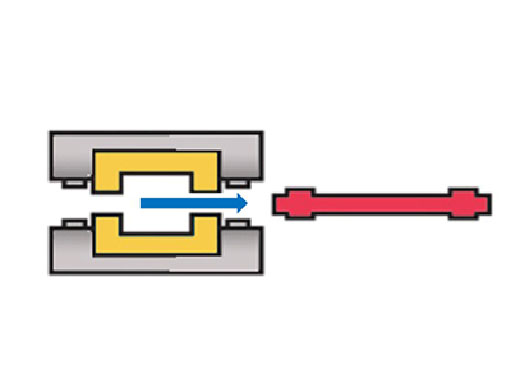

Hot plate welding process

Part halves are placed into and securely gripped

Part halves are placed into and securely gripped

Part halves are placed into and securely gripped

Part halves are placed into and securely gripped

Part halves are placed into and securely gripped

Part halves are placed into and securely gripped

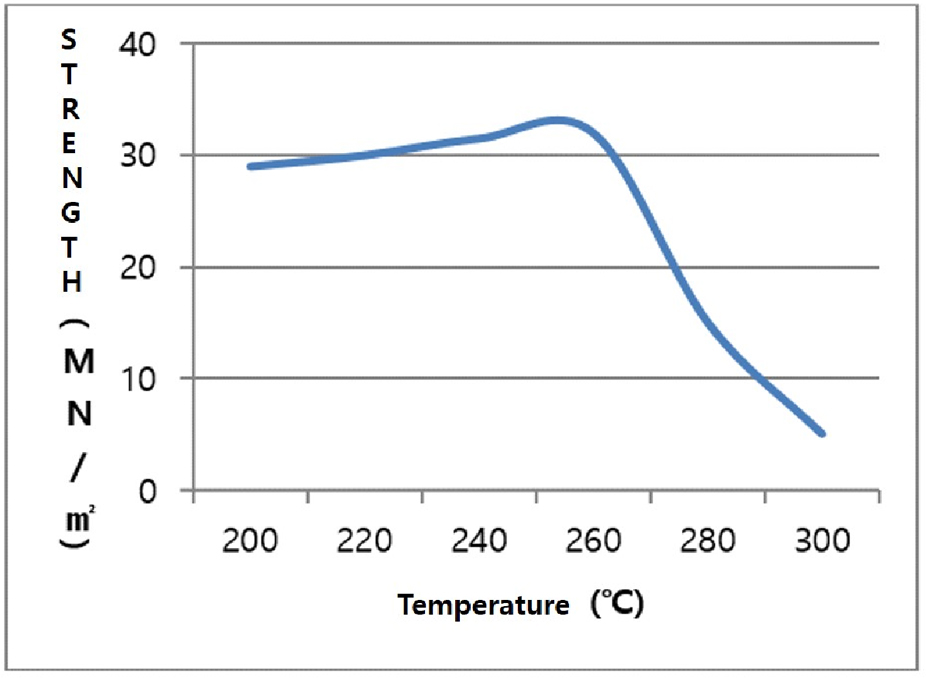

Temperature and Strength

In case of PP, When you selected 240°C(appropriate temperature), You can obtain strength of similar the parent metal. But the ambient temperature can be changed in many ways. So It is heated to 20 degrees higher temperature than the melting point of the material.

Figure shows the best weld strength at 260°C. and strength drops rapidly at 260°C or more.

Hot plate welder application