Ultrasonic welder

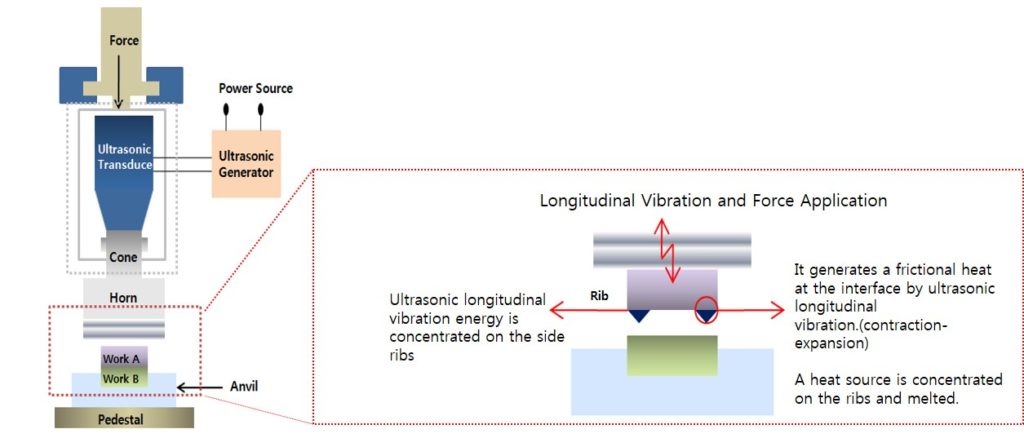

When the ultrasonic vibration is applied for the first time, the asperity of the welded surface of the welded surface becomes very fast. The surface protrusions concentrate more stress than other parts, consuming most of the large strain and vibration energy, so that the protrusions of the welded part are melted and heat is transferred to the periphery. The molten layer is thinly formed on the entire welded surface at this moment and diffusion is performed in a short time due to continuous vibration of the ultrasonic wave and welding is performed.

Such ultrasonic welding is performed in such a short time that it is not comparable with the method of using the adhesive. Since the adhesive force is strong and the welded portion is clean, it is possible to reduce the cost and improve the productivity and quality.

(* Ultrasound: sound wave with frequency of 10kHz or more)

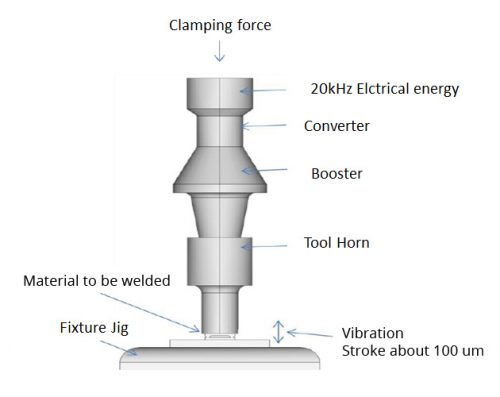

- Oscillator (Generator): Generates an electrical signal

- Converter: convert electrical signal to mechanical vibration

- Main Booster

- Amplify the vibration generated by the vibrator.

- Use the main horn between the vibrator and the tool horn to compensate for the difference between the vibration amplitude generated from the vibrator and the practical amplitude for welding the plastic.

- Tool Horn: Directly touching plastic to transmit vibration

- Jig: The part that fixes the complex

Ultrasonic welding operation

Advantages of ultrasonic welding

- The work environment is clean and efficient because no adhesive or solvent is used.

- Instant adhesion time is effective for quality and productivity.

- It has good watertightness and airtightness due to strong adhesion. (Water tightness: property that water does not penetrate well, airtightness: property that does not pass through gas)

- No preprocessing and post-treatment are required, thus doubling the production efficiency.

- The difficult mold structure of the product can be easily solved.

- Low power consumption and semi-permanent machine life, low maintenance cost.

- It is easy to use and the product is uniform, improving the quality and production efficiency.

- Automatic and semiautomatic batch process operations are possible.

Characteristics of ultrasonic welding

- Heat the plastic itself.

- Since the surface to be welded is subjected to ultrasonic vibration, it is blown away by dirt, liquid, etc., so that it does not need to be cleaned.

- It is easy to move relative to the welding material with less appearance friction.

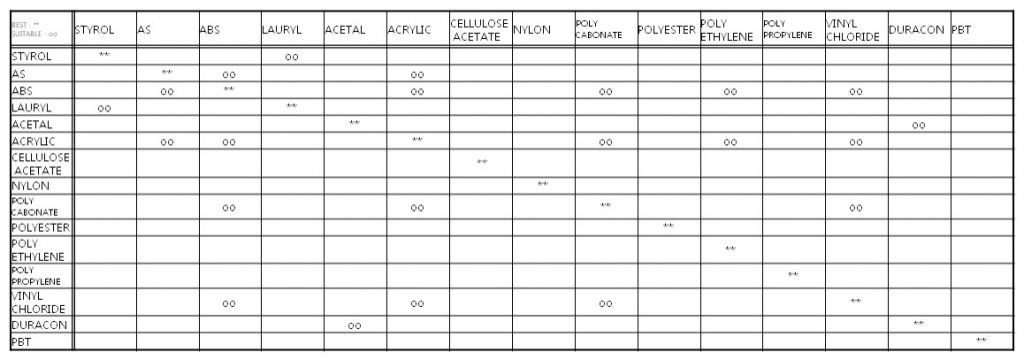

- Different materials can be welded.

- If the output of the tool horn is sharpened and ultrasonic waves are applied, fusing is possible.

- It is possible to generate heat by transferring ultrasonic waves to the plastic in the state away from the tool horn.

Overview of plastics that can be welded together

Ultrasonic welder application

Automotive parts

Automotive door Schweissen/ Automotive bumper Sensor/Insert/Sun Visor Hinge /Automotive Wheel Guide/ Automotive dashb

Medical

Mask / Oxygen Mask / Thermometer / Filter

Home Appliances

LED lamp / USB / USB hub / cell phone charger / Bluetooth earphone / remote control / SD memory card

Fabric welding

Cushion / Industrial filter / Mask / Fabric cutting / Fabric modeling

Food

Cake & Bread Cutting/ Tea bag welding / Drink packaging / Snack food welding / Liquid packaging container

ETC

Air conditioning Cross fan / Washing machine Otobaransu / baby toy / chopsticks / baby toilet / cosmetic case