Play Video

Spin Welder

The rotary welding process is a process of welding a thermoplastic component having a rotationally symmetrical shape using heat generated by rotational friction in a welding line.

The rotary welding machine rotates another part of the welded part while it is stopped, applies pressure vertically, generates frictional heat due to rotational friction at the welded part where the two parts close each other, and pressurizes and welds them.

The rotary welding process can produce semi-permanent and high-quality welded products. In addition, there are hermetic seals, low cost of equipment, easy assembly, efficient energy operation, no ventilation, There are various advantages such as no material requirement.

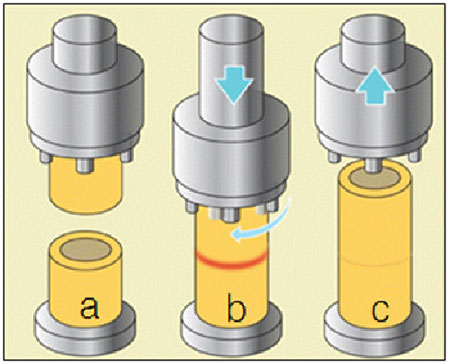

Operation of rotary welding machine

- Rotating welding insert product

- Rotating the upper jig lowering and rotating after the pressing

- Rotating the upper jig after completion of the rising

Advantages of spin welding machines

- The weld strength is 90% or more of the strength of the raw material when the same kind of material is welded.

- Precision of length after welding is ± 0.3mm

- The degree of confidentiality is 100%. (Degree of airtightness: the degree to which internal fluid, gas, and liquid do not leak to the outside when constant pressure is applied)

- There is no change after a long period of time after welding.